Anybody can have the capacity to carry out aluminum welding as well as repair service conveniently as well as swiftly. Nonetheless, only few can accomplish the greatest as well as most dependable aluminium welding, aluminum construction as well as components repairs.

This is because this sort of welding requires a great deal of precise focus as well as attention. And if you wish to be just one of minority successful welders, you need to pursue the rules of the thumb when you are looking for the welding equipments that will certainly aid you prepare your method to a successful aluminium welding endeavor.

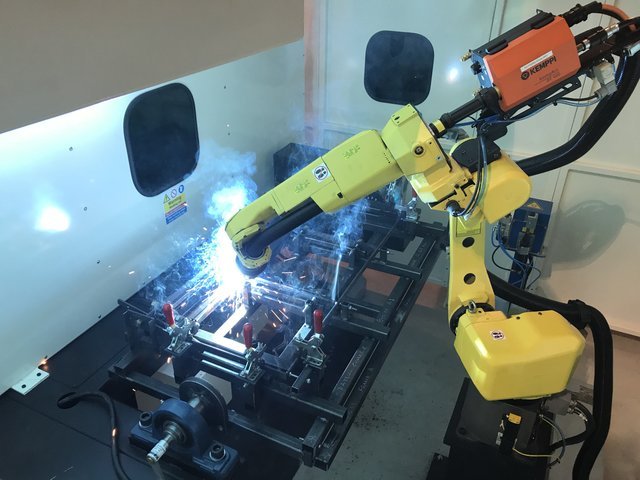

Preparing the materials and also equipments is the crucial action in welding aluminum. With the correct tools at hand, you will surely have the ability of performing your job at any given time. Applying the appropriate and also dependable techniques in welding aluminum is additionally needed in order to see higher results. You require to aesthetically inspect all of the weldments in order to ensure a first-rate gas tungsten-arc welds as well as gas-metal welds of aluminum alloys.

Even for those who are currently experienced as well as educated in steel welding, welding light weight aluminum alloys is capable of offering somewhat a difficulty. Low melting factor of light weight aluminum alloys along with superior thermal conductivity can just cause shed via unless welders go after authorized procedure in welding.

In addition, feeding aluminum welding cord all through gas-metal-arc-welding provides a test for the reason that the cord has lower column strength, softer than steel, as well as is inclined to link at the drive roll. To victory over these conflicts and challenges, welders and also operators need to go behind the guidelines and paraphernalia-collection principles offered. Know more resources and view it now thru the link.

Base-metal training: To perform aluminium welding, employees need to cleanse the base material and also eliminate every hydrocarbon as well as aluminum oxide air pollution from cutting solvents and oils.

Warming up: Warming up the aluminum work item can avoid weld cracking. Pre-heating temperature level should not look at 230

F-use a heat screen to avoid getting too hot.

Journalism on approach: By means of aluminum, continuing the weapon far from the weld pool as opposed to pulling it will certainly offer an enhanced cleansing task, condensed weld infectivity, and much better shielding-gas exposure.

Travel speed: Light weight aluminum welding needs to be attained “quickly and also warm.” Various from steel, the high thermal conductivity of light weight aluminum states use of voltage setups, hotter amperage and also exceptional weld-travel prices.

Defending Gas: Argon, due to its top quality clear out action and also seepage profile, is the most common safeguarding gas made use of when welding light weight aluminum.

Power-spring alternative: When choosing a source of power for aluminum GMAW, mostly consider the method of pulse or transfer -spray-arc.

Wire feeder: The favored techniques for feeding supple light weight aluminum wire long distance is the press and also pull technique, which utilizes an enfolded wire-feed breakfront to take care of the wire from the environments.

Welding weapons: Make use of a different gun lining for aluminum welding. To delay wire chaffing, make an effort to keep back both ends of the liner to get rid of breaks in between the gas and the diffuser liner on the gun.